Equipment

Blender

- Flowrate from 1 m3/min to 19 m3/min

- 2 Cummins engines

- 1 sucking pump

- 2 dry chemicals injectors

- 6 pumps for fluid chemicals with flowmeters

- Open Surefire mixer 2 m3

- 2 electromagnetic flowmeters at the outlet and at the sucking line

- 3 augers for sand or proppant 12”

- Densitometer

- Fully automatic operation with switching to manual one (if required) from both the blender and frac data vanList of measures recommended to improve the labour conditions

Hydration Unit

- For both dry & liquid chemicals

- 6 pumps with flowmeters

- 31,6 m3 tank

- Automatic tank levelling

- Tank Mixers

- Sentrifugal pump

- Built-in-line viscometer

- pH-meter

- Temperature sensor

High-Pressure Pumper

- CAT 3512 – 2500 hp Engine

- FMC WQ2700 Quintuplex pump

- 15K PSI (1000 atm) max. pressure

- Outlet iron 3” 1502 SPM

- Plungers Automatic greasing system

- Emergency Shutdown system

Data Van – Lab

- Automatic operating of 20 frac pumpers, blender, hydration unit and chem van

- LIME software for designing and controlling frac treatments on-line

- All frac parameters recording

- Built-in lab for frac fluids and chemicals’ testing

- 40 kW Generator for data van and wellsite lighting

Hot Oiler

- 2500 kW Power

- 6 000 liters diesel Tank

- Automatic operating

Steam Boiler Truck

- The unit is designed for removing paraffin from tubing, heating and washing vehicles with LP or HP wet steam

- 5m3 water tank

- Time required to get the steam from the boiler – less than 10 min.

- Max. steam temperature – 310 degrees C.

- Cabin truck operating

Chem Van

- 10 chem pumps complete with Micro Motion flowmeters

- 10 chem tanks of 1 400 litres

- Automatic chem system

- External heat-insulation

- Burst proof heaters and light

- Remote communication with data van

AKN Vacuum Truck

- Cummins (340 hp) Engine

- Steel tank, bottom and sidewalls are 5 mm thick, round profile, external frame

- 10 000 l Tank. Heating with a steam truck.

- Temp sensor on the pump with chassis engine emergency shutdown and alarm signal in case of temp limit extended

- Sensor of maximum filling with chassis engine emergency shutdown

- Delivery-suction hoses – 2 pcs, 6 m long (petrol-and-oil-resistant, armored, antistatic) complete with a kit of spark-proof quick unions of clamps type

Acid Truck (SIN 32)

- It is designed for transporting and pumping inhibited solutions of hydrochloric acid, clay acids, as well as solutions of alkalis and salt solutions

- 7 m3 tank with a corrosion-resistant coating

- Three-plunger pump, model SIN-32, two high-speed gearboxes, chrome plungers

Water tank 2000m3

- 2 000 m3 Volume

- Protective geo-liner (geo-textile)

- Thermo-cover and thermally insulated walls to maintain water temperature in cold seasons

CT Unit

- Manufacturer: "Stewart & Stevenson Inc". Model TCR-15000

- A mobile Coiled tubing unit designed for well servicing operations (acid treatment, cleaning, drilling).

- Coil of 7500 meters 2" (50.8 mm).

- Mounted on a Peerless semi-trailer, model CH-55-24A.

- 600 hp Power

- Equipped with weight control system, preventer and hydraulic accumulators

Cementing Twin triplex Pumper SPM TWS600S

- Manufacturer: Crown Industries Ltd. Model CRW-920.

- Total power of triplex pumps - 1150 hp

- One pump is equipped with 4.5 ”diameter plungers, the second is 3.5” diameter plungers

- The unit is designed for continuous mixing and pumping cement slurry in oil wells. The pumps are driven by two 460 hp Cummins N-14 diesel engines each.

- Mounted on a 3-axle semi-trailer.

- Maximum flow rate 950 l / min.

- Maximum pressure 15000 PSI (1000 atm.)

- Automatic 7-speed gearbox.

- Remote control option

Nitrogen Unit

- Manufacturer: Surefire Industries Ltd. Model 3200-0018

- Nitrogen Unit of "flaming" type

- Minimum nitrogen injection rate - 15 m3/min, Maximum -170 m3/min

- Three-plunger pumping unit. Mounted on a Stellar Stepdeck semi-trailer, model MID RATE N2

- 600 hp

- Max. admissible working pressure - 15000 PSI (1000 atm.)

- Max. N2 tank capacity - 11 tons.

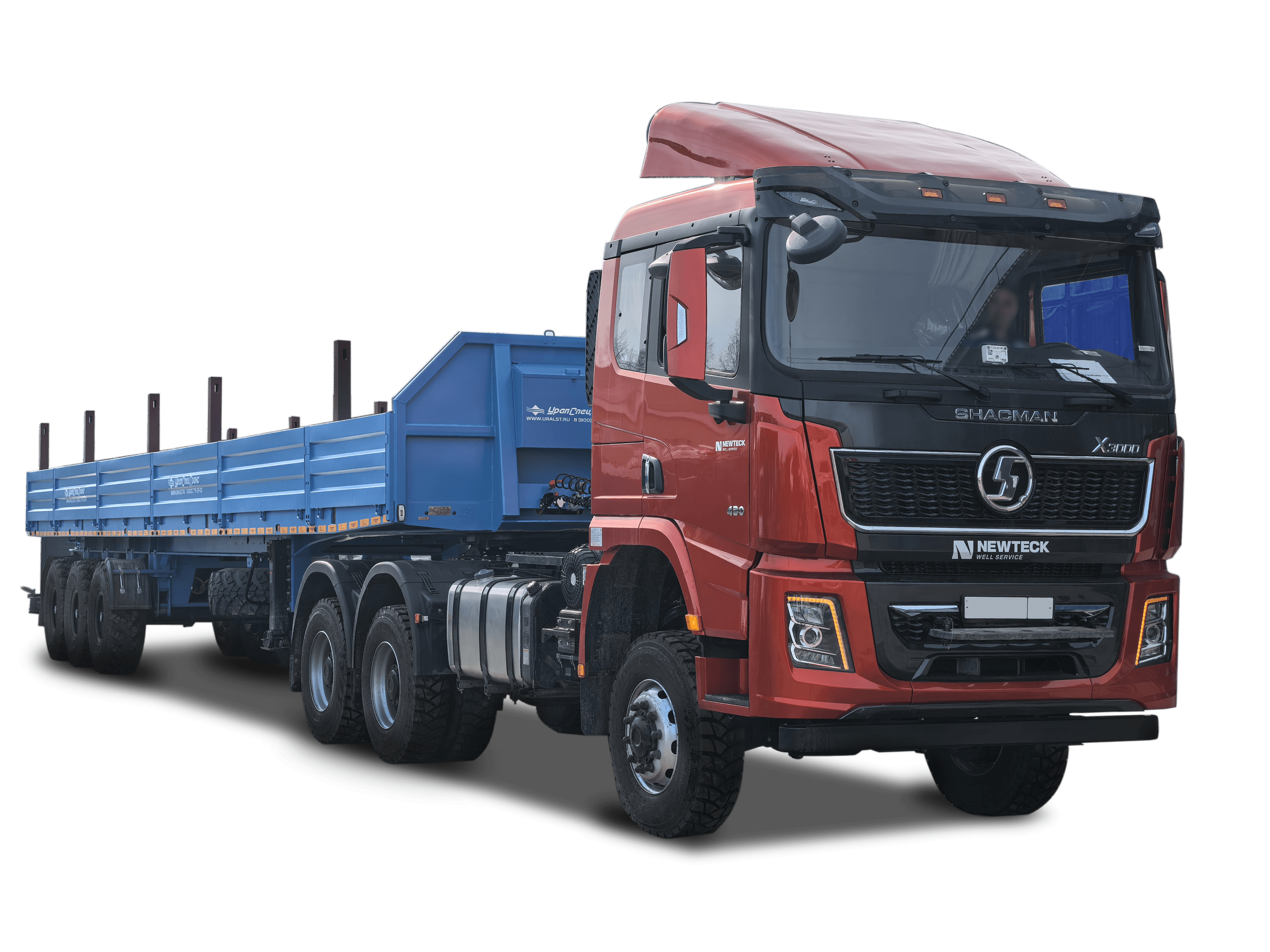

Semitrailer van

- Manufacturer: ПАО "УралАвтоПрицеп"

- Cargo weight 37500 kg

- Curb weight of the semitrailer 10800 kg

- Gross trailer weight 48300 kg

- Number of wheels 6+1 pieces

- Maximum speed 70 km/h

Curtainsider semi-trailer

- Manufacturer: ООО "УралСТ"

- Curb weight of the semi-trailer 9 400 kg

- Cargo weight 30 000 kg

- Gross weight of flatbed semi-trailer 39 400 kg

- Number of axles/wheels 3 / 6 + 1